What is FDN Technology?

Fused Deposition Modelling (FDM) was invented in the 1980s by Scott Crump, co-founder and chairman of Stratasys. This method uses a thermoplastic filament, which is heated to its melting point and then extruded, layer by layer, to create the specified three dimensional part.

How Fused Deposition Modelling (FDM) Works

Usually objects or parts for FDM start out as computer-aided design (CAD) files. Before beginning the build process this has to be converted to an .STL file; a format that the computer will recognise. 3D printers that run FDM build the parts layer-by-layer from the base, heating and extruding the thermoplastic filament.

FDM is the ideal process for:

- Durable one-off parts

- Prototypes for fit and form testing

- Prototypes for functional testing

- A small series of high-quality parts with strength and stability

- Complex jigs and fixtures

FDM materials at Ogle

ASA – A UV stable blend of ABS

Currently we stock this in tan and black, however, for larger projects we can provide a range of different colours. This is one of the most popular materials or FDM, because ABS is a widely used production material, which means you receive all the benefits without the high production tooling costs and lengthy timescales of other methods. The support structure is soluble, allowing for intricate and otherwise impossible designs to become a physical reality.

PC ISO

An industrial grade thermoplastic which is most commonly used in the food and medical industry. This is because once it is sterilised it confirms with ISO 10993 USP class V1 medical certification.

Ultem 9085

This is one of the miracle materials of FDM. Available with us in a natural tan colour. This is most widely used in the aerospace sector where its temperature resistance and FST certification are vital. Want to know more about this miracle material? Click here.

Fused Layer Modelling Synonyms

- Fused Layer Modelling

- Fused Layer Manufacturing (FLM)

- Fused Filament Fabrications (FFF).

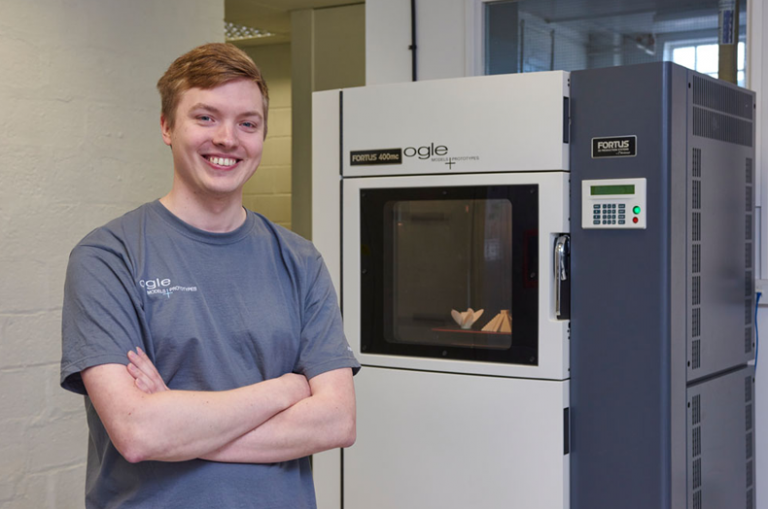

At Ogle, we’ve continued to invest in our FDM capabilities, and as with all our processes, we approach each design on an individual basis and then decide what the best orientation for the part to be built in. This ensures that critical geometry is accurate and any features, such as clips, will function fully and the aesthetics will be as intended. The Fortus 400 machine offers the widest range of colours and material properties for tooling and prototyping.

Want to talk?

For more information about this article or to speak to one of our expert team, call us

on +44 (0) 1462 682 661 or email us at [email protected].